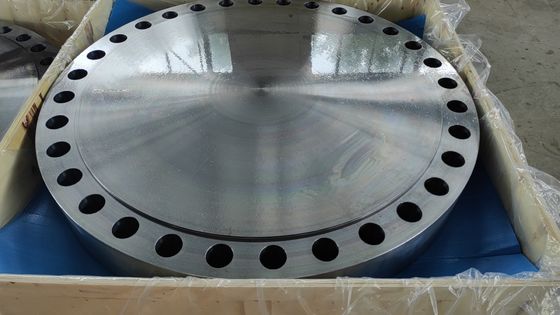

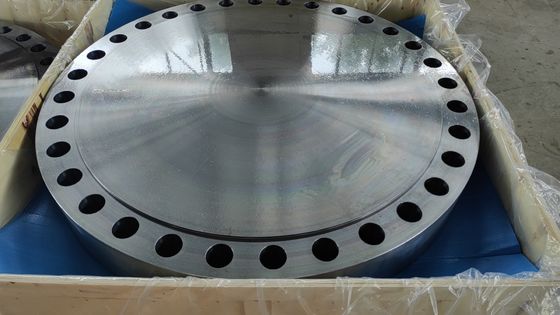

強化された密封性能 溶接首フレンズ ASME B16.5 DN80 150級

1製品説明

ウェルドネックフレンズ (Weld Neck Flange) は,長くて角型ハブで特徴付けられるパイプフレンズの一種で,バットウェルド (周縁バットウェルドの一種) を通して徐々にパイプに溶接される.この設計は,高完全性のアプリケーションに不可欠です通常は,優れた強度のために鍛造鋼から製造され,通常1MPaから25MPaまでの高圧環境に対応するように設計されています.フレンジは2つの主要な国際標準システムの一部です: ヨーロッパ系 (PN系) とアメリカ系 (クラス系)

2主要な製品パラメータ

パラメータ 詳細

タイプとコード 溶接首フレンズ (WN)

適用される基準 HG/T 20592-2009 (欧州PNシリーズ),HG/T 20615-2009 (アメリカのクラスシリーズ),GB/T 9115-2010,JB/T 82-94

定数直径 (DN) 幅広い範囲で利用可能で,通常はDN10から上へ

圧力評価 ヨーロッパのシステム (PN): PN10からPN250,アメリカのシステム (クラス): 150から2500級.

密封面型 浮き顔 (RF),男性-女性 (MFM),舌-溝 (TG),リング関節 (RJ). RJ顔は,しばしばPN160/Class 600以上の圧力に使用されます.

共通材料 炭素鋼,ステンレス鋼 (304, 304L, 316, 316L, 321),合金鋼 (クロム・モリブデン,クロム・モリブデン・バナジウム)

製造プロセス 鍛造してる

3製品用途

溶接首フレンジは,要求の高いサービスのために設計されており,以下に広く使用されています.

高圧・高温パイプライン

燃やす,爆発する,または有毒なメディアを輸送するパイプライン.

温度や圧力の変動が大きいアプリケーション

石油・ガス,化学加工,製薬,造船などの重要な産業.

4製品メリット

優れた強度とストレスの分布: 長い,角型ハブは,パイプからフレンズへのスムーズな移行を提供します.ストレスの濃度を大幅に低下させ,フレンズの硬さと変形耐性を高めます..

優れた密封性能: 堅牢な構造と様々な密封面オプションにより,厳しいサービス条件下で漏れ止め密封を維持するのに理想的です.

高完全性接続: バット溶接接続は,完全な浸透溶接を提供し,疲労耐性が高いし,フィレット溶接よりも信頼性があります.振動や屈曲モメントを伴うアプリケーションに適しています.

耐久性: 高圧 (~25 MPa まで),高温,繰り返し回転 に 耐える

よくある質問

Q. OEMサービスを受け入れるのですか?A: そうです

Q 無料のサンプルを貰えますか?A: そうです. 送料は,サンプルが大きすぎない場合にのみ負担します.

Q. 製品に自分のロゴを貼ってもいいですか?A:はい,私たちはプロフェッショナルな製造業者なので,OEMサービスも可能です.

Q. 報名を受けたい場合は,どんな情報をお伝えしましょうか?A: サイズデザイン基準,材料,パッケージ,量など...可能な場合は,確認のためにいくつかの写真とデザインを送信してください.そうでなければ,我々はあなたの参照のために詳細を関連製品をお勧めします.

Q: 配達期間は何ですか?A: その通りEXW,FOB,CIFなどを受け入れます.あなたにとって最も便利なものを選択できます.

Q: パッケージは何ですか? 商品はどのように送りますか?A: その通り通常は木製のパレットなどのご要望に応じて 船で運送します.航空輸送もオプションで,需要に応じて調整できます.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!